ECONOMIC BLAST CABINETS - PEKO series

Cost-effective solutions for abrasive surface treatment

KEY FEATURES

PEKO series blasting cabinets (economical solutions)

The most popular Sant-Tech blast cabinets (sandblasters), with the emphasis on quality design and good value pricing.

KEY FEATURES

PEKO series blast cabinets and sandblasters are among the most popular, cost-effective solutions for abrasive surface treatment in Sant-Tech offer.

All parts of the machines are solidly welded, lacquered with hammer finish paint and built using only high quality parts to guarantee their long life and trouble-free operation. Due to their friendly pricing, sturdy construction and low operating costs, PEKO blast cabinets are a popular choice among car mechanics, automotive repair shops, as well as many other clients who need access to fast, easy and cheap abrasive blasting in their line of work while handling objects of various sizes and materials. PEKO series blast cabinets come in two sizes, PEKO 100 and PEKO 140. They use injection blasting or pressure blasting systems.

PEKO series standard cabinet equipment include:

-

industrial nozzles of tungsten carbide

-

pressure regulator with a big and legible manometer, for precise control of the sandblasting process

-

advanced pressure blasting system (in pressure blast cabinets), which allows to increase the velocity of abrasive media flow up to 4 times and speed up the sandblasting process as a result

-

convenient and practical foot pedal control

-

PCV coated blasting gloves lined with cotton and additionally insulated for comfortable blasting performed in colder environments, manufactured in accordance with Directive 89/686/EEC on personal protective equipment.

-

glove mounting that allows for their easy exchange

-

high quality reliable BNP blast gun

-

efficient overhead lightning in the cabinet combined with innovative air circulation solution to ensure good visibility during sandblasting,

-

sandblast hoses for injection blasting,

-

heavy duty durable hoses for shot blasting (in pressure blast cabinets)

-

double cabinet door insulation for 100% air tight, dust-free operation,

-

removable tempered glass panes

-

cabinet window with no blind spot

Optional equipment for PEKO series blast cabinets (possibilities of machine customization)

-

rubber mats coating of the cabinet inner walls

-

turntable with 100 kg capacity (650 mm diameter)

PEKO series cabinets – technical parameters

| MODEL: | PEKO-100 | PEKO-140 |

| machine dimensions (mm) width x length x height | 1050 x 850 x 1780 | 1450 x 1060 x 1780 |

| workspace dimensions (mm) width x length x height | 1000 x 750 x 700 | 1400 x 1000 x 700 |

| weight (kg) | 120-150 | 140-170 |

Dust collectors for PEKO series blast cabinets

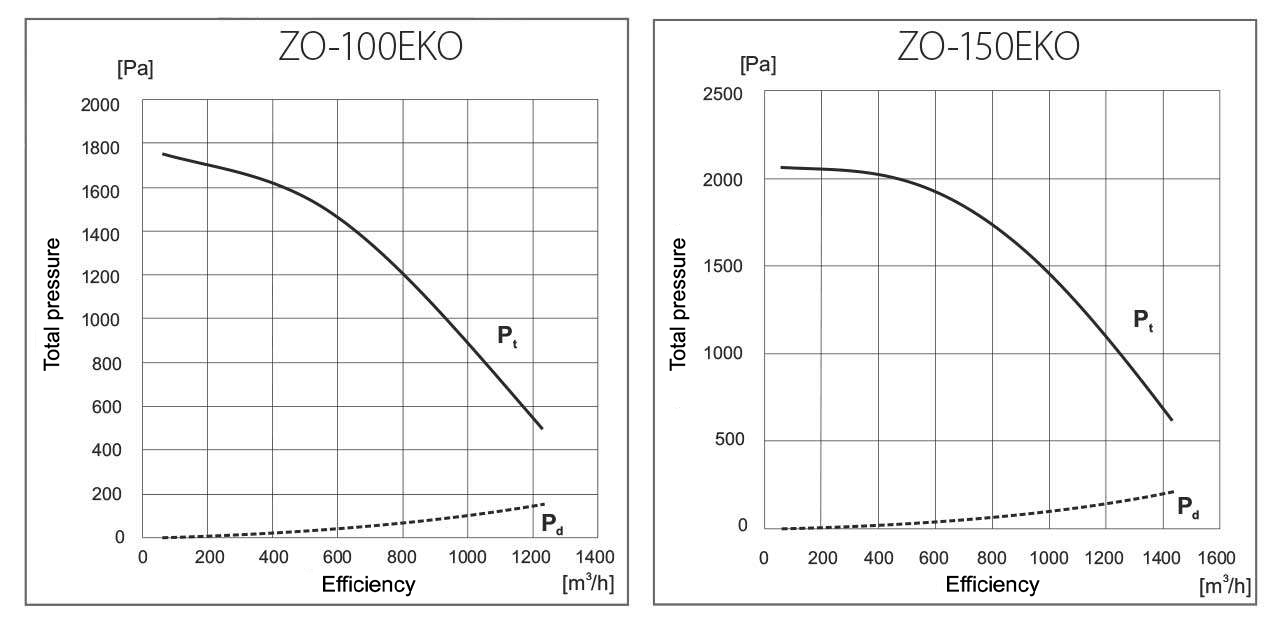

For best performance of PEKO series blast cabinets, we have developed ZO-100EKO and ZO-150EKO dust collectors. These differential pressure dust collectors are designed to extract and filter fine dust and/ or small chips of metal, wood or plastic that are the byproduct of various industrial processes, in particular abrasive blasting.

ZO-100EKO and ZO-150EKO standard equipment include:

-

centrifugal fan

-

high-quality polyester filter cartridges

-

easy-to-handle waste bin

-

manual control valve to control suction strength

ZO-100EKO and ZO-150EKO are adapted for continuous operation.

Optional equipment for EKO dust collectors (possibilities of machine customization)

-

fully automatic filter cleaning system (automated filter shaker)

-

higher density polyester filter cartridges (260 g/m2) in place of the standard ones

EKO dust collectors – technical parameters (pola zażółcone również do podmiany na ulotce PEKO, żeby było tak samo)

| MODEL: | ZO-100EKO | ZO-150EKO |

| machine dimensions (mm) width x length x height | 610 x 750 x 1000 | 610 x 750 x 1600 |

| power (kW) | 0,55 | 0,75 |

| filter surface area (m2) | 6 | 10 |

| filter capacity (m3/h) | 1200 | 1500 |

| inlet diameter DN (mm) | 100 | 150 |

| filter density (g/m2) | 180 | 180 |

| weight (kg) | 70 | 100 |

EKO dust collectors performance graphs: